Since its foundation, Yingli has invested a lot of time and effort in the R & D and innovation of zero-carbon technology and been committed to promoting the development and application of clean energy, and dedicated its greatest strength to China’s environmental protection and green development. Between 2017 and 2008, Yingli invested nearly 3.5 billion Yuan in research and development, built a large technical team of 2,500 members, with 350 core research and development personnel, many senior industry experts and foreign experts, and had has more than 700 scientific and technological innovation projects. The team has undertaken a number of national science and technology projects, two "973" projects, five "863" projects, 1 science and technology support project, and 3 international cooperation projects, got 13 international patent applications, 2,137 Chinese patent applications, and prepared or participated in the preparation of 55 standards, including international standards, national standards, industry standards and local standards. Since 2012, Yingli has ranked first in the number of patent applications and grants within the industry in China for consecutive 5 years. It has been successively approved and established the national R & D platform, such as “State Key Laboratory of Photovoltaic Materials and Technology”, “National Energy Photovoltaic Technology Laboratory”, “National Enterprise Technology Center” and “International Joint Research Center for Photovoltaic Technology”, to promote the industry’s development through the research and development of advanced technology.

Meanwhile, Yingli actively contacts with the international community, cooperates with each other, learn internationally advanced technology, and actively carry out R & D innovation so as to improve the efficiency of our products, and enhance its ability to protect environment and reduce environmental pollution. Yingli has worked extensively with The Holland State Energy Research Center (hereinafter referred to as "ECN"), Norway Industrial Technology Research Institute (hereinafter referred to as "SINTEF"), American Innovalight Corporation, Singapore Nanyang Technological University, The University of New South Wales, Australia, DUPONT USA, British DEK Solar Energy Corporation, and speeded up the transformation of achievements and increase the level of technology by introducing foreign advanced research technology.

Research and develop effective products with the aid of large technology platform to provide society with clean power equipment.

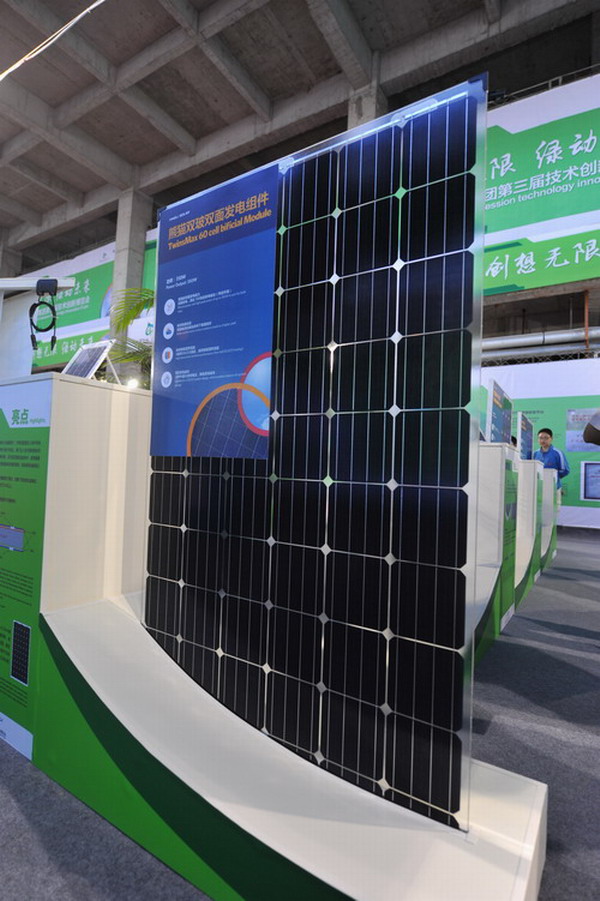

In order to improve the power generation efficiency of PV module and make them generate more green power for people, Yingli has begun to focus on the research of type-N monocrystalline bifacial high-efficiency cell, and become the first manufacturer which realized the mass production of type-N monocrystalline bifacial high-efficiency cell in China with the aid of the mass production of “PANDA” technology.

The technologically upgraded second-generation "PANDA" battery technology adopts ion implantation to improve battery efficiency. Its front power generation efficiency can reach 21.5%, and rear efficiency can be 92% of the front efficiency. The front power generation efficiency of Bificial series photovoltaic component (60 pieces of cells) manufactured with second-generation PANDA battery can exceed 300 watt, the rear of the component can maximally contribute 30% of the front generating capacity, the actual power generation is over 380W, and the equivalent component efficiency exceeds 23%, leading in similar technology of the industry.

Light energy purifying components pioneered the use of the world's advanced photocatalyst purification technology. The photovoltaic components manufactured with photocatalyst spraying made with the latest generation of nanometer titanium dioxide active material in the world can be used not only for power generation, but also for improving air quality. After being treated with light energy purification treatment technology, photocatalyst purification membrane will form on the surface of photovoltaic component, which reduces and decomposes harmful substances, such as smoke, formaldehyde, nitrides, and sulfides through the action of sunlight into innoxious substance, such as water, carbon dioxide and nitrogen and sulfur compounds. This will help achieve the effect of continuous purification of the environment, and will not produce secondary pollution, and turn to be safe, efficient and energy-saving. The experimental data show that using 1 piece of light energy purification component can achieve the environmental purification effect of planting 32 trees.

Yingli light energy purifying components are widely used in factory (especially near polluting enterprises), civil roof, power plant built by reusing abandoned polluted land, and building’s curtain wall, which can realize the function of light energy purification on the basis of increase the amount of generating capacity of components, reduce component cleaning operation and maintenance costs, improve the overall benefits of photovoltaic power station, and have a good application prospect.

How to effectively reduce the cost of photovoltaic system and improve the efficiency of power generation will still be the core issue of photovoltaic industry development in the future. In July 2015, Yingli launched a 1,500V high pressure resistant component, which passed the certification of UL1,500V on March 21, 2016 because of its high resistance to high pressure. The 1,500V component has many advantages in the return on investment of the system. It can save the overall system balance cost and reduce the loss of the AC and DC side cables and the low-voltage side winding of transformers; the volume reduction of the equipment (inverter and transformer) is also helpful to reduce the labor cost of photovoltaic system. It may reduce the cost of cable investment by 20%. Increasing DC voltage to 1,500V is an important change in reducing cost and increasing efficiency.

In 1999, Yingli undertook China’s first demonstration project of polysilicon solar cells and application systems with an annual output capacity of 3 megawatts, which laid a foundation for the popularization of solar energy in China.

At the beginning of national promotion and the development of clean energy, Yingli’s "69 Fen" bidding national concession bidding project bidding in 2009 broke the myth that "The price of solar energy is too high to be reached” and made the concept of “manufacturing green power that people can afford” deeply rooted among the people. In 2010, Yingli surrendered part of the profits of $90 million to support the construction of the national golden sun demonstration project, which has accelerated the popularization of solar photovoltaic power generation of China.

In order to respond to China’s call of environmental protection, the company audited cleaner production by following the principle of energy conservation and emission reduction, realized monitoring data networking with Baoding Municipal Environmental Protection Bureau, invested a lot of money after repeated tests and researches, and carried out waste water comprehensive management projects, including the recycling of concentrated water, the recycling of reclaimed water and the deep processing of waste water and gas on the basis of reaching the standards. Strengthen energy measurement, statistics and analysis in the link of production, make full use of the energy consumption indexes, regularly organize various units to analyze the energy consumption, and make measures to cope with abnormal energy consumption and supervise and implement them. Strengthen the transformation of energy conservation and emission reduction technology, and organize all units to declare, manage and popularize energy saving and consumption-reducing projects.

Globally, more than 17GW Yingli PV modules have provided an unfailing supply of green power for all types of users, accounting for about 5.67% of the total global total installed capacity. With average annual generating capacity of 18 billion kwh, they are expected to reduce 10 million tons of carbon dioxide emissions worldwide every years, which is equal to stop driving over 2 million small cars or planting 500 million trees.

Yingli 10 MW golden sun demonstration project were all built on the roof and shed of factory buildings inside Yingli Industrial Park, which was completed in 2011 with a total investment of 178.2 million Yuan, the total installed area of 103,092 square meters, and the construction period of 1 year. The project has remarkable effects in energy conservation and emission reduction. After being completed, it is expected to generate 230.2711 million kWh of electricity, save 92,100 tons of standard coal, reduce the emissions of 210,000 tons of carbon dioxide, 721 tons of sulfur dioxide, 615 tons of nitride, and 1,410 tons of dust in 25 years, with the total benefits of emission reduction expected to reach 89.3 million Yuan. State Key Laboratory of Photovoltaic Materials and Technology and National Energy Photovoltaic Technology Key Laboratory Projects have an installed capacity of 1.3 MW, the annual power output of 720 thousand KW, save 288 tons of standard coal, and can reduce 697 tons of CO2 emissions, 6.8 tons of SO2 emissions and 6 tons of soot emissions.

According to the needs of the users, Yingli combines transportation, storage, loading and unloading, carrying, packaging, circulation & processing, distribution, information processing and other functions to meet the requirements of users. Moreover, it gradually implements "zero inventory", "trend management", "integrated management", "terminal distribution" and "green packaging" to reduce consumption in the logistics process.